Company

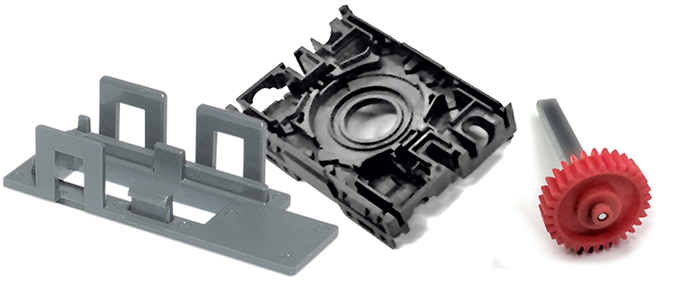

GIACOPLAST is a company specialised in the moulding of thermoplastic and thermosetting materials that has acquired professionalism and national and international market knowledge, also in the field of plastic processing, operating with highly specialised experience and professional skills for more than 40 years.

Starting as a craft company and undergoing profound transformation and growth, GIACOPLAST is today not only an established company in its sector, but is also a highly specialised company that can count on modern and innovative equipment and machinery, as well as on modern and efficient technologies to manage the entire production process to manufacture products that fully meet project requirements and specifications.

Through the combination of experience acquired in the past and investments in advanced technologies to manage the production process, GIACOPLAST is able to manufacture plastic products with high technical performance to meet every market need in all the sectors in which it operates, having and ensuring its Customers a high level of operational and production process flexibility.

The highly specialised and experienced workforce ensures constant support to Customers as well as attention to product detail in every phase of the process and in every industrial sector such as automotive, electrical, textile, oil & gas, mechanical, electromechanical, aeronautical, textile, medical and pharmaceutical and telecommunications.

GIACOPLAST is able to offer its customers "tailor-made" products, thus offering increasingly complete solutions in a constantly developing market; in fact, it is able to support the Customer from the initial idea towards the best result in terms of reliability, productivity, timing and costs, through its strengths, including:

Technological innovation of production process machinery and management systems; Extremely high precision of the products manufactured in compliance with the established tolerances through a planned and methodological Control System and full compliance with and punctuality of delivery times.

High professionalism in the initial management and preliminary analysis Service and maximization of Quality, while minimising rejects as well as significantly reducing waste, with a view to safeguarding the Environment; Operational and production process flexibility.

Efficiency of the entire work process with a consequent increase in economic competitivity.